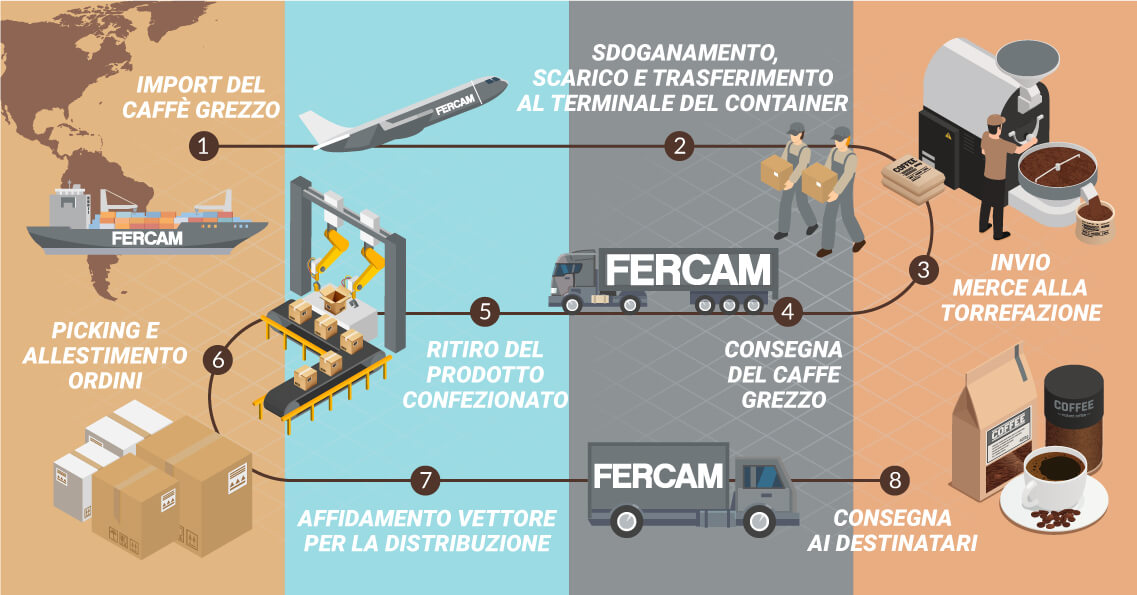

The coffee supply chain, a 360° logistics and transport experience

Let’s travel with a coffee bean along its long journey, which will lead us from plantations in the tropical and subtropical areas of the world, to the roasting machine, and finally to our own cup. What stages does the process involve and which logistics and transport services are involved in this long chain?

The supply chain through different phases, methods and skills

The different divisions of a multi-specialized company such as FERCAM can support each phase of transport for a product such as coffee with dedicated expertise, presenting the customer a single interlocutor for the entire flow.

The long distance that separates manufacturing Companies from European roasters is usually bridged by sea or air transport. Upon arrival of the containers in the country of destination, all the customs clearance procedures are then carried out, after which the coffee can be unloaded and transferred to the terminal. The goods are then temporarily stored in the warehouse, from where they will be progressively sent to the roasting plants at the time of the order by the customer.

In roasting, the raw product undergoes the first essential phase of processing: the roasting transforms the green bean, almost tasteless and odorless, into the aromatic and crunchy bean we all know well. The cooking times and temperatures are different depending on the variety, and the expert roaster, especially if the processing is done on an artisanal level, will be able to modulate the cooking in an artful way, to release all the aroma of the bean. Coffee can be left in grains or ground, to be then packaged or encapsulated.

And here the transport and logistics partner immediately comes into play again: the finished and packaged product is once again received in the logistics warehouse. Here, upon receipt of an order, picking and preparation activities begin, to prepare pallets with the goods to be sent to the final recipient. Competent and precise collaborators prepare the necessary documentation and pass the baton to the distribution department, which takes care of the final route, also called the last mile, up to the shelves of the store where we can buy it as a final consumer.

From here to the satisfaction of a steaming cup of coffee the step is now very short...