AgriEuro doubles the logistics hub of Piacenza in collaboration with FERCAM

(Bolzano, 20th February 2023) AgriEuro signs with FERCAM the agreement for doubling the logistics center of Piacenza: expansion of space by mid-2023 and quadrupled number of shipments by 2024.

AgriEuro, Spoleto company leader in the online trade of machines for agriculture and gardening, signs a new collaboration agreement with FERCAM, historical partner of the brand, for the doubling of the current logistics headquarters in Piacenza. The new distribution site will be fully operational by mid-2023.

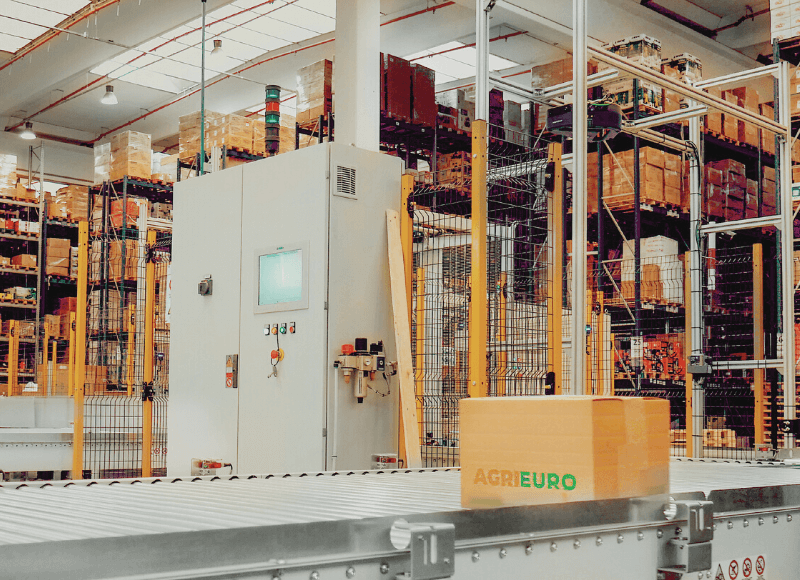

The growth of e-commerce does not stop and, by the middle of this year, AgriEuro will be able to count on the doubling of the spaces of its most recent logistics hub, inaugurated in Piacenza together with FERCAM in 2021 and destined for the storage of small and medium-sized goods in the catalog (0-80 kg). The current location thus expands by an additional area of 12,500 square meters and a capacity of 14,000 pallet places, and is added to the logistics centers of Bologna Interporto and Novara (managed by FERCAM for AgriEuro) and the warehouse of Spoleto, in the province of Perugia, managed by AgriEuro.

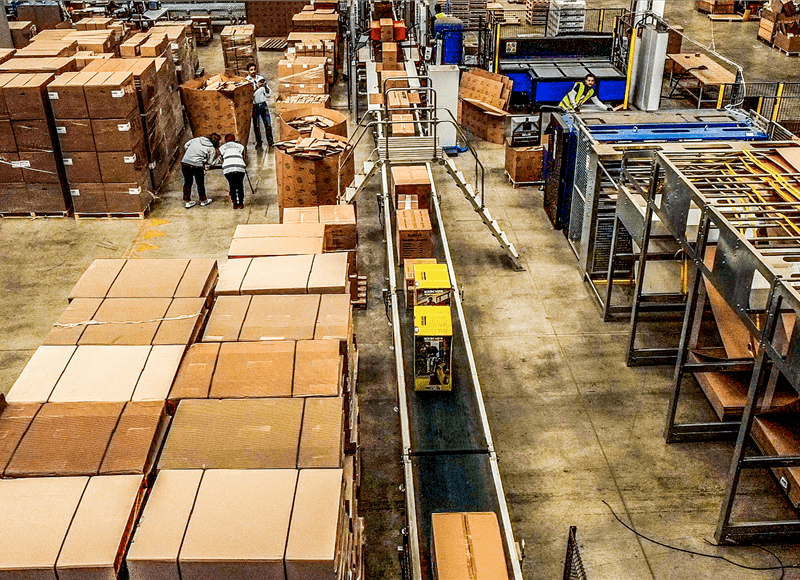

The new logistic area will accommodate a second line of semiautomatic packing, similar to that in use in the center of Piacenza today operating, but specific for small and medium sized products from 0 to 40 kg. The new machine has been designed ad hoc by an internal office in AgriEuro, in collaboration with the technical team of FERCAM and together with the two partner companies for the physical construction and installation of the plant. The new packaging system will be even more technologically advanced, characterized by a higher working speed and a production capacity up to 4 times higher than the model currently in operation.

«All small and medium-sized products weighing up to 40 kg will be gradually transferred to the additional distribution platform, while in the currently active location will remain items from 40 up to 80 kg. Splitting the process into two specific subcategories with related packaging methods will be optimized the entire supply chain of the logistics center» reports Roberta Melis, Business Process Manager AgriEuro.

The doubling of the Piacenza facility, together with the production characteristics of the new packaging system that will be installed, put into operation and tested by mid-2023, will not allow AgriEuro only to double the number of products evaded, as you might think, but they will allow the company to set up more than triple the shipments currently managed by the single pole, or even quadruple them by 2024.

«We are very satisfied with the agreement reached with FERCAM, historical partner in the logistics management of our business since 2012 with the inauguration of the headquarters in Perugia. The doubling of the distribution center in Piacenza and the installation of a new semi-automatic machinery will increase the efficiency of our goods packaging system, ensuring a productivity up to four times higher than the current one, helping to speed up our shipping service» says Filippo Settimi, CEO of AgriEuro. «The application of a second box is not a simple procedure, it obviously takes longer. With the increase of the surface available at the Piacenza site, the installation of the new machinery and the optimization of the distribution processes, we will be able to overcome this impasse, ensuring even higher levels of efficiency».

The logistics center of Piacenza was designed, from the beginning in 2021, for the management of small and medium-sized products of the AgriEuro catalog, that is, with a weight from 0 to 80kg. Thanks to the use of a customized semi-automatic packaging line, a customized double box is applied to all products in order to reduce the damage suffered by goods during transport, ensure the anonymity of the items shipped and completely eliminate the use of plastic material, thus increasing the quality of the service offered. This second packaging is in fact 100% ecological: made entirely of cardboard (80% recycled) and tape paper, without the use of wooden pallets, replaced again by cardboard, the pack is easily disposed of by the private citizen. A service that will be ulteriorly strengthened through the new line of semiautomatic packing that will be installed in the additional logistic center of Piacenza.